In the ever-evolving landscape of technology, materials play a crucial role in driving innovation across various industries. One of the most exciting advancements in lightweight technology is the emergence of Triopd Carbon Fiber, a material that is not only redefining performance standards but is also set to revolutionize multiple sectors by 2025. Renowned for its exceptional strength-to-weight ratio, Triopd Carbon Fiber offers manufacturers an unprecedented opportunity to enhance product design, durability, and efficiency.

As industries grapple with the demands for sustainability and high-performance solutions, Triopd Carbon Fiber stands out by providing an eco-friendly alternative that does not compromise on quality. This revolutionary material enables the creation of lightweight structures without sacrificing strength, making it an ideal choice for sectors ranging from aerospace to automotive and sports equipment. As we delve into the possibilities presented by Triopd Carbon Fiber, it becomes clear that its impact will shape the future of product development and industry standards, marking it as a key player in the race towards innovation.

Triopd Carbon Fiber is a cutting-edge material that stands out due to its exceptional strength-to-weight ratio. This unique property makes it incredibly valuable across various industries, from aerospace to automotive. The key feature of Triopd Carbon Fiber is its composition, which combines advanced polymers with carbon filaments, resulting in a lightweight yet durable material. It is engineered to withstand extreme conditions while maintaining structural integrity, which is a significant advantage for manufacturers aiming to enhance performance without heavy components.

In addition to its strength and lightweight nature, Triopd Carbon Fiber offers excellent resistance to corrosion and fatigue. This durability extends the lifecycle of products made from this material, reducing the need for frequent replacements and thus lowering overall costs. Furthermore, the versatility of Triopd Carbon Fiber allows for various applications, including sporting goods, medical devices, and high-performance vehicles. Ultimately, the integration of Triopd Carbon Fiber into industry processes not only boosts efficiency but also drives innovation, paving the way for future technological advancements.

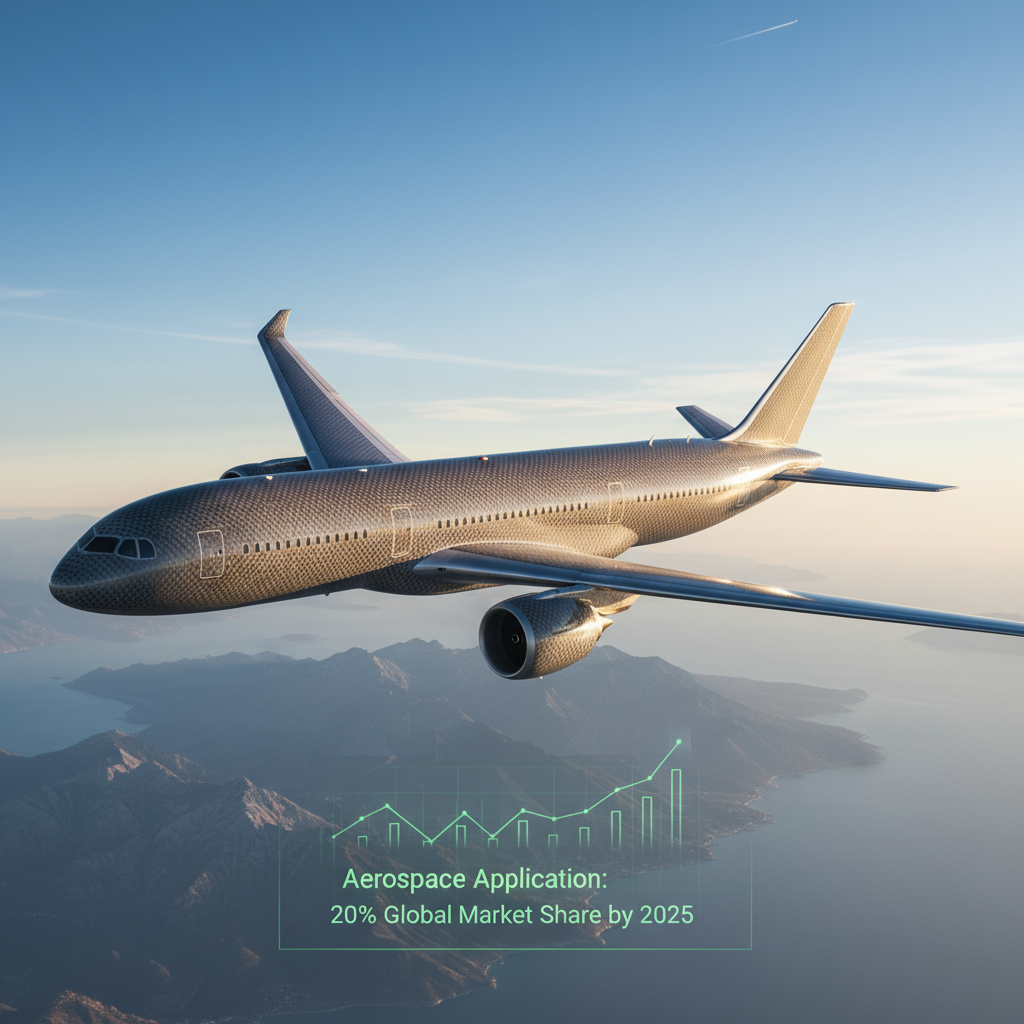

Triopd Carbon Fiber is making significant strides in various industries, thanks to its unparalleled strength-to-weight ratio and versatility. In aerospace, for instance, the material is used extensively to enhance fuel efficiency and reduce emissions. Reports indicate that aerospace applications could account for around 20% of the global carbon fiber market by 2025, driven by the need for lightweight alternatives that contribute to greener aviation solutions. This shift not only facilitates improved aircraft performance but also provides manufacturers with a competitive edge in an increasingly eco-conscious market.

In the automotive sector, Triopd Carbon Fiber is transforming vehicle design by making cars lighter and safer. According to a study by the Automotive Composite Conference, carbon fiber components can reduce vehicle weight by up to 50%, significantly influencing acceleration and fuel economy. Electric vehicle manufacturers are particularly drawn to this material, as a reduction in weight translates to longer battery life and enhanced driving ranges. Furthermore, the growth of electric and hybrid vehicles is projected to propel the demand for carbon composites in the automotive industry, with estimates suggesting an increase to over 30% market share by 2030.

Beyond aerospace and automotive, Triopd Carbon Fiber is also finding applications in sporting goods, construction, and wind energy, illustrating its adaptability and potential to revolutionize multiple sectors. The material's high modulus and fatigue resistance make it ideal for high-performance bike frames, wind turbine blades, and even structural elements in modern architecture. As industries continue to prioritize lightweight technology, the significance of Triopd Carbon Fiber is only expected to grow.

Triopd Carbon Fiber has emerged as a game-changer in the realm of lightweight materials, setting a new benchmark when compared to traditional substances like aluminum and steel.

Unlike these conventional materials, Triopd Carbon Fiber boasts a remarkable strength-to-weight ratio, making it significantly lighter without compromising durability. This property not only enhances performance in various applications but also contributes to energy efficiency, particularly in the automotive and aerospace sectors, where reduced weight can lead to improved fuel economy.

When conducting a comparative analysis, one can observe that while traditional materials offer robustness, they often do so at a greater weight cost. For instance, aluminum, although lighter than steel, still falls short against Triopd Carbon Fiber's superior mechanical properties. Furthermore, the versatility of Triopd Carbon Fiber allows for intricate designs and complex shapes that are difficult to achieve with traditional methods. As industries increasingly seek to innovate and minimize their environmental footprint, the transition towards Triopd Carbon Fiber represents a significant shift towards more efficient and sustainable practices in manufacturing and design.

Triopd Carbon Fiber is at the forefront of modern lightweight technology, driven by innovative manufacturing techniques that enhance its properties and applications across various industries. The production of Triopd Carbon Fiber involves advanced processes such as automated fiber placement, resin transfer molding, and 3D printing. These methods not only reduce material waste but also allow for greater design flexibility, enabling manufacturers to create complex shapes that meet specific performance requirements. With its exceptional strength-to-weight ratio, Triopd Carbon Fiber is increasingly used in automotive, aerospace, and sports equipment.

When working with Triopd Carbon Fiber products, consider these tips for optimal results. First, ensure proper curing times during manufacturing to maximize the material's strength and durability. Additionally, evaluate the environmental conditions, as temperature and humidity can influence the curing process and the final product quality. Lastly, maintain precise control over the fiber orientation during placement, as this can significantly impact the mechanical properties and performance of the finished product. Adopting these practices will help harness the full potential of Triopd Carbon Fiber technology in your projects.

As industries continue to seek innovative materials that enhance efficiency and reduce weight,

Triopd Carbon Fiber stands out due to its remarkable properties.

This advanced composite material not only provides exceptional strength-to-weight ratios but also boasts superior durability and resistance to environmental factors.

Future trends indicate that

Triopd Carbon Fiber will play an increasingly vital role in sectors such as aerospace, automotive, and sporting goods,

where performance and weight reduction are paramount.

The evolution of Triopd Carbon Fiber technology is poised to drive significant changes in manufacturing processes.

With the advent of new production techniques, such as 3D printing and automated layup processes,

the integration of Triopd Carbon Fiber into various applications will become more efficient and cost-effective.

This shift will not only streamline production timelines but also allow for greater design flexibility,

enabling engineers to create complex structures that were previously unachievable.

As industries embrace these advancements, we can expect to see Triopd Carbon Fiber becoming a cornerstone of

modern engineering solutions.